Waterbourne car painting- the painting process and things to keep in mind

The procedure of car painting using water base is ananlougous to that of solvent-based car painting with some minor difference. The process includes 8 steps and many more sub-steps during the process. Additionally there are some issues that technicians need to keep an eye for during their work. The waterbourne car paint is fairly new on the market so its weaknesses should be kept in mind to avoid unwanted mistakes.

What is waterbourne car paint and why should we use it

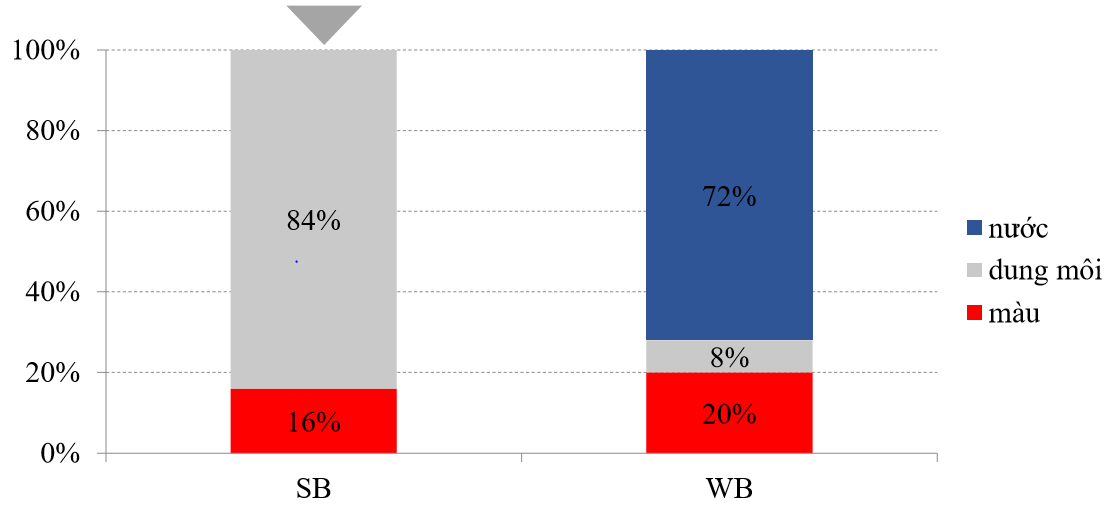

Water-based car paint contains mostly water instead of solvent like solven-based car paint, while having higher ratio of color. This genre of paint is becoming increasingly widespread lately. Since most of its component is water, the harmful wastes we usually see from car painting products are significantly lower (90% less than its solvent-based counterpart)- which is perfect for the evironmental scenario of the world right now. The international market are switching to using waterbourne car paint more and more to meet the legal and societal evironment standards at the EU, USA, Canada, Australia, etc.

The procedure of waterbourne car painting

The waterbourne car painting procedure is similar to the process of solvent-based car painting (visit automotive refinish- coating process for more information). The process begins by trying out and indicating the ratio of the desired colors. Before painting we need to prepare the work surface, adjusting the parameter of the equipments and prepare the paint by the ratio.

Prepare the painting surface by sanding the area with increasing grit, then clean with Nax E3 Silicon Off and wipe with wet and dry cloth. After that dampen the area with oil remover.

The paint sprayer have the pressure in the range between 1.5-2.0 bar (28-30 PSI). The technicians need to determine the numbers of paint layers and its thickness.

- Solid: spray 2 layer of paint and then blow wind to evaporate solvent until faded, spray an extra layer if lack coverage.

- Metallic: spray an underclear layer at the retention area with a distant of 10 cm around the area; spray 2 layer of paint and blow wind to evaporate solvent until faded, add another layer with pressure of 1.2-1.4 and distance of 30 cm.

The difference between the waterbourne painting procedure and its solvent-based counterpart is the wind blowing process for 5-7 minutes between the layers. This is because the drying time of water-based paint is affected by temperature, humidity and wind speed while solvent-based is affected by temperature only. Although the conditions for working with waterbourne car paint is more complex but the end result is better and working time is more sufficient.

Note: the varnishes layer have to be applied only after waiting for 7-10 minutes after the last paint layer and another layer could be applied after 24 minutes. After 20 minutes of solvent evaporation at 250C, P800 or P1000 sanding paper and air blower could be used at the faulty area to adjust.

Equipments used in the waterbourne car painting procedure

The standard equipments for this process are:

- Wind blower (individual or attached to shelf) or built-in high temperature wind blowing system in the painting chamber.

- Air compressor with standard oil filter and air blowing system.

- Triple level filter: 3μ, 1μ and 0.01μ.

- Anti-rust paint sprayer with low pressure (specialized type is not necessary).

- Paint pouring cap.

- Plastic paint cups (do NOT use metal cups).

- Nylon paint filter 125 microns.

- Paint card made from alluminium or hydrophobic material.

- Non-stick cloth.

Note: The painting chamber should be clean, have sufficient light and ventilation (800-1000 lux, 0.25-0.3 m/s); two seperate spraying gun should be used for paint and varnishes to avoid cross contamination; using sticky cloth to clean could result in silica or solvent mark in the final product.

Frequent oversight during the waterbourne painting procedure

The mistakes that executor often make during the waterbourne car painting procedure are uneven surface handling (rough) and dust on the working surface resulting in fault in the final product.

Relative News